Compañt and Rhino

Stack plate reamers Compañt and Rhino

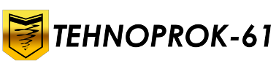

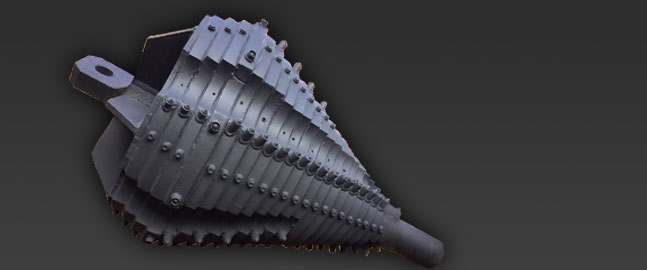

Stack plate reamer "Compañt" is designed for drilling stable rocks up of up to 6 Protodyakonov hardness scale, and soils: loam, clay with pebble inclusions, sandstone plates, soft limestone, and sandstone. Among the common HDD reamer types, it is the most versatile. The reamer body is quite lightweight, but durable, designed as several joint rings. Rows of cutters feed the drilled soil into the grooves with flushing monitors. Typically, reamers have 3 grooves, larger diameter reamers have 6 grooves.

Double rows of cutters, swivel and inverted cone can be fitted. Reamers with a diameter of more than 800 mm are manufactured with a body that is not filled with bentonite. When in operating condition, they have the mass of steel they are made from and the air inside the reamer provides zero buoyancy. The required amount of water as a ballast can be filled through the plug in the casing. These reamers drill a soil ring equal to the difference in diameter between the previous and current reamer. The well does not change its path after underreaming.Stack plate reamer «Rhino»

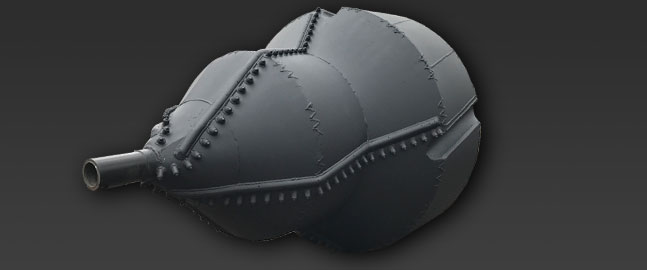

The cutting and sealing stack plate reamer Rhino is a stepped reamer made of stacking rings, 40 mm wide, with an enlarged calibrating part. This type of reamer is designed exclusively for the HDD complexes of “maxi” and “mega” types, which have a drill rod with a diameter of at least 100 mm and a maximum torque of 20,000 to 90,000 Nm. It has stiffening ribs inside, and the structure of the body of the large diameter reamers is not filled with bentonite, which reduces their working mass. The steel part of the body is protected from abrasion. For emergencies, when the reamer needs to be pushed back, there is a tapered part of the body on the back of the reamer. The reamer can be equipped with a double row of cutters and an integrated swivel.